Behind the scenes: Sushiro’s high-tech conveyor-belt sushi experience, from kitchen to table

- We go behind the scenes of Sushiro to see what makes the conveyor-belt sushi chain tick, from kitchen to table

- There’s a lot of cool technology to streamline processes and ensure consistency

- We also learn that salmon and salmon belly are the second and third bestsellers, but what’s number one?

Sushiro is undoubtedly one of Singapore’s most popular Japanese restaurants.

A convenient and efficient conveyor-belt experience, paired with affordable but quality sushi — what’s not to love?

Just grab a seat, look through the electronic menu on the tablet, and order through the system and everything gets sent to you within minutes.

Or, if you want, you can stare down the conveyor belt until something tantalising comes your way. Sorta like a spinning wheel generator for the indecisive.

Some may not know this, but conveyor belt sushi or “kaitensushi” has been around for almost 70 years, first introduced to the world by Genroku Sushi in Osaka in 1958, as a solution to manpower shortages.

Sushiro also originated from Osaka, almost three decades later in 1984.

It was originally a traditional sushi bar named Tai Sushi, before the owners decided to change things up, so that more of the public could try its sushi.

They built their new restaurant on the motto of “tasty sushi for all”, and today, Sushiro is one of the biggest conveyor-belt sushi brands in the world.

But have you ever wondered what exactly goes on behind the belt that keeps this well-oiled machine running so smoothly?

We definitely have. So we decided: Why don’t we just see for ourselves?

Into the kitchen

Getting approval wasn’t easy. It is a chain restaurant from Japan, after all, and the Japanese are notoriously strict about their kitchen standards and hygiene.

Thankfully, the Japanese headquarters thought: “Why not?” and we soon found ourselves at Sushiro’s Thomson Plaza branch on a Wednesday afternoon.

Thomson Plaza’s manager Liu Yan Jun, 37, greeted us and gave a rundown of what to expect, before guiding us to the staff area for a hygiene ritual, prior to entering the kitchen.

The washing area was located right outside the kitchen — a simple two-tap sink set-up, stocked up with soap, disinfectant and a placard for Sushiro’s 10-step hand-washing procedure.

It requires extremely thorough scrubbing, going into every nook and cranny, starting from your inner palm and ending at your wrist.

The most interesting aspect? You have to count to 10 for each hand and each part.

What’s even more interesting is that you’ll be guided by an electronic metronome perched right above the sink that pings in a steady 100BPM rhythm.

Two minutes later, our hands were sterilised and smooth and we were ready to enter, donning hair nets and masks and following Yan Jun into Sushiro’s kitchen.

A machine for everything

Our first impression of the kitchen was, well, it was just like any kitchen — clean, industrial, fitted with steel counters and awash in bright fluorescent light.

But venturing further in, we found ourselves in the heart of operations at Sushiro, the conveyor belt “assembly line”.

The setup is quite straightforward — just a row of steel counters filled with screens and plates, backed by tinted windows separating the preparation area from the restaurant’s main dining space.

There are two belts that connect the kitchen to the outside world — the standard conveyor belt below, which keeps a constant flow of food in circulation around the restaurant, and the auto-waiter express lane above, which serves out specific orders to each table.

When orders come in, the screens will alert the staff, who quickly assemble the sushi, before plopping them onto the auto-waiter.

The process is very fast and that’s partly due to the technology Sushiro uses in its restaurants.

While you’d often see sushi chefs in upscale omakase restaurants delicately pressing the shari (sushi rice) into balls by hand, Sushiro has a machine for that.

Making shari balls is effortless with this. It’s loaded up with plates and has a container to dump the rice into. When activated, it instantly injects the rice into a mould and sends it out on a plate.

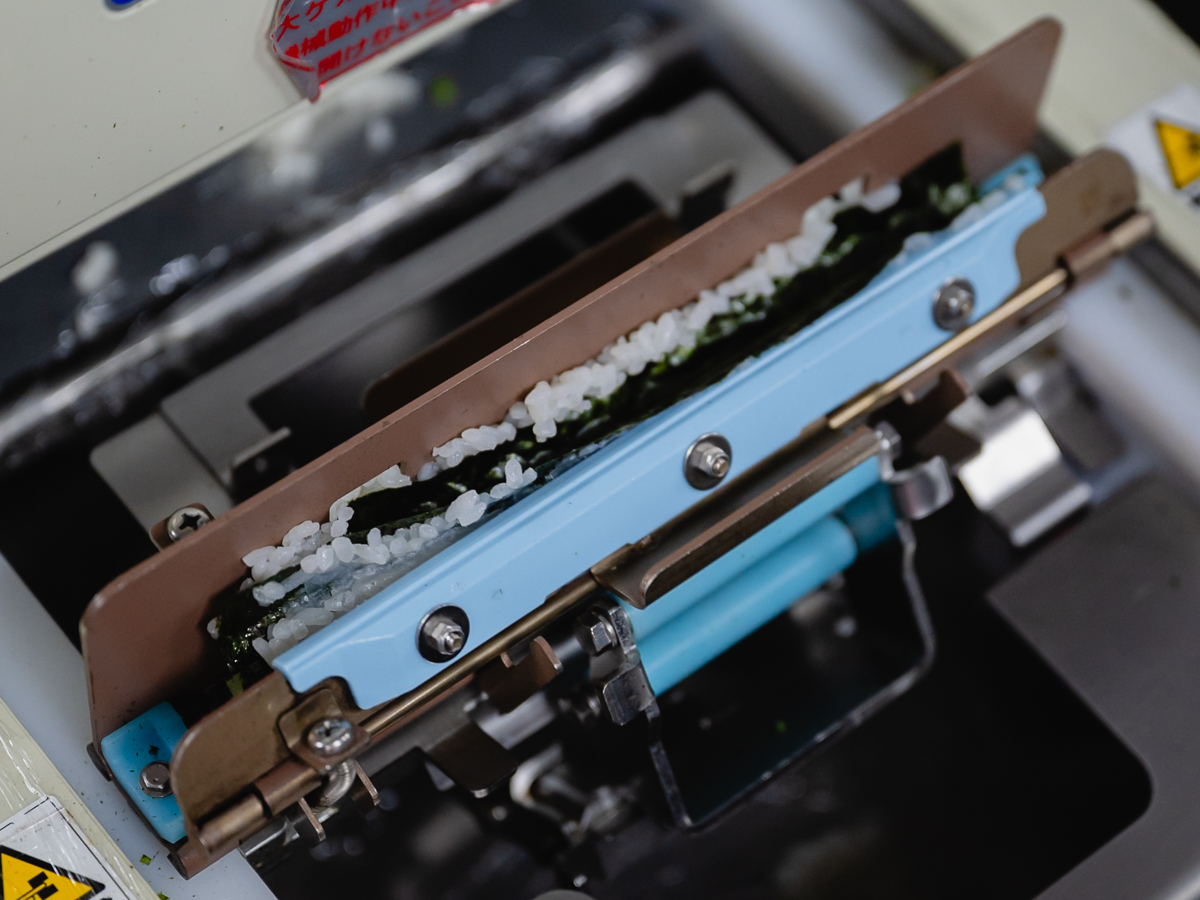

Similarly, you’d find a machine for making gunkan (“boat-shaped” sushi wrapped with seaweed) bases, one for winding up handrolls, and even one that mixes vinegar into rice.

With a front row seat to all the action, we watched as they assembled all our orders and everything was done, in a blink of an eye.

Now, it’s time to go out and eat.

Freshness is king

After we grabbed our sushi plates off the conveyer belts, we also grabbed Yan Jun to join us for a chat about running the restaurant.

The Sushiro Thomson Plaza manager has been with the company for four years and knows the ins-and-outs of the store.

Our first question was something we’d always wondered: How does Sushiro keep everything so consistent, especially when dealing with such high volumes?

Many people who have visited Sushiro in Japan itself would vouch for its consistency in quality, even in Singapore.

Yan Jun explains: “Most of our ingredients are imported from Japan and we have stringent hygiene standards, including hourly hygiene checks in the kitchen.”

But it’s not just about hygiene; Sushiro also tries to deliver the best, freshest sushi from the kitchen.

That includes mixing the vinegar into the rice, right after it’s done cooking to ensure the flavour seeps in. And they try to use the rice within four hours for optimal freshness, too.

Yan Jun adds: “All the plates are tracked and after they travel for 350m on the main conveyor belt, they will automatically be disposed of to ensure freshness.”

Oh, and another cool part about the whole system? Once you’re done eating, you’d probably notice staff scanning your plates with a handheld device to generate your final bill.

It’s actually because every plate is chipped to ensure a streamlined checking out process!

Sushiro’s food

Here’s another burning question: What are the best-sellers?

According to Yan Jun, the top three in Japan are tuna, young yellowtail and shrimp tempura nigiri.

But here in Singapore, we all know a certain orange fish has everyone obsessed. So as expected, we see salmon belly and salmon sushi taking up two of the top spots.

However, the No 1 spot, surprisingly, belongs to the chawanmushi!

Well, we share the love because we also ordered our own portion of chawanmushi with scallop (S$3.50) — it’s the kind of luscious, custardy comfort everyone needs on rainy days.

Of course, we also had to go for the classic salmon (S$2.30) and salmon belly (S$2.30).

These are nothing fancy, but they are fresh, silky and would satisfy any cravings perfectly. Hey, it’s fuss-free, simple sushi done right.

Of course, we had to also get a portion of the Japanese best-seller, tuna (S$2.30) and it’s rich and firm, just the way we like it.

Honestly, most dishes at Sushiro won’t fail you — consistency and dependability is the brand’s MO and the quality more than justifies the price tags.

But we’ve acquired a deeper appreciation for Sushiro, after witnessing what goes on behind the scenes, and we found ourselves enjoying the experience just that tiny bit more now.

Also, we just really like watching the conveyor belt smoothly running in the background while we eat, to be honest. It’s therapeutic.

This was a hosted tasting.

For more ideas on what to eat, read our stories on our intimate look into the life of a Teochew porridge boss and the 22 year-old who just started her own donut business!